Gear Shaping on:

[Wikipedia]

[Google]

[Amazon]

Gear shaping is a

Gear shaping is a

Gear Shaping Machines

Retrieved on January 13, 2009. ;Notes {{DEFAULTSORT:Gear Shaping Gears

Gear shaping is a

Gear shaping is a machining

Machining is a process in which a material (often metal) is cut to a desired final shape and size by a controlled material-removal process. The processes that have this common theme are collectively called subtractive manufacturing, which utilizes ...

process for creating teeth on a gear

A gear is a rotating circular machine part having cut teeth or, in the case of a cogwheel or gearwheel, inserted teeth (called ''cogs''), which mesh with another (compatible) toothed part to transmit (convert) torque and speed. The basic pr ...

using a cutter. Gear shaping is a convenient and versatile method of gear cutting. It involves continuous, same-plane rotational cutting of gear.

Process theory

The types of cutters used for gear shaping can be grouped into four categories: disk, hub, shank, andhelical

Helical may refer to:

* Helix, the mathematical concept for the shape

* Helical engine, a proposed spacecraft propulsion drive

* Helical spring, a coilspring

* Helical plc, a British property company, once a maker of steel bar stock

* Helicoil

A t ...

cutters. The cutters are essentially gears that are used to form the teeth. This method of gear cutting is based on the principle that any two gears will mesh if they are of the same pitch, proper helix angle, and proper tooth depth and thickness.

Process characteristics

By using a gear-shaped corresponding cutter that is rotated (in relation to a blank gear) produces the gear teeth. The cutters that are rotated are timed with the workpiece. This process producesinternal gear

A gear is a rotating circular machine part having cut teeth or, in the case of a cogwheel or gearwheel, inserted teeth (called ''cogs''), which mesh with another (compatible) toothed part to transmit (convert) torque and speed. The basic p ...

s, external gears, and integral gear- pinion arrangements.

Process schematic

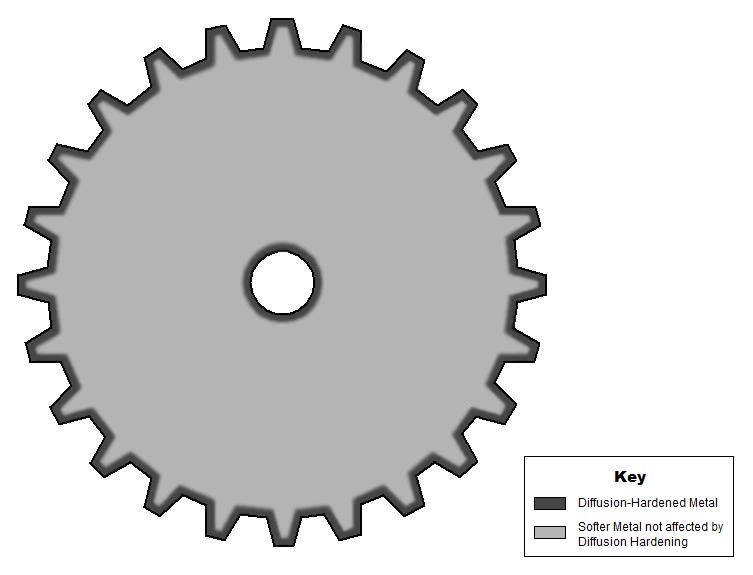

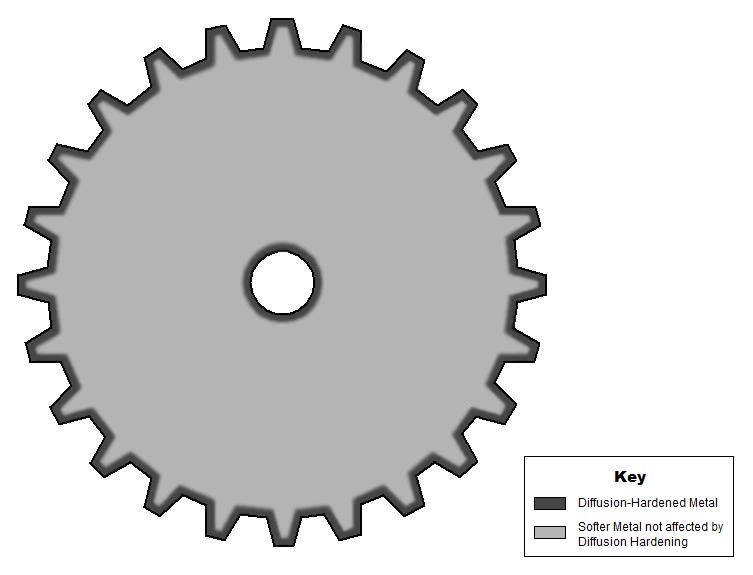

The process of gear shaping uses a toothed disk cutter which reciprocates in axial rotations. The workpiece (or blank gear) rotates on a second shaft (spindle). The workpiece is aligned with the cutter and it gradually feeds into the cutter while rotating. If a two-step process is used, all tooth spaces are partially cut before finishing.Setup and equipment

The machine used for gear shaping generally consists of a base, columnspindle

Spindle may refer to:

Textiles and manufacturing

* Spindle (textiles), a straight spike to spin fibers into yarn

* Spindle (tool), a rotating axis of a machine tool

Biology

* Common spindle and other species of shrubs and trees in genus ''Euony ...

, and an arbor. The gear cutter is mounted on the spindle, and the gear blank is mounted on the arbor. The cutter reciprocates up and down while the workpiece is gradually fed into the cutter. At the end of each cutting rotation, the spindle is retracted slightly to discourage any more cutting into the new cut teeth of the gear.

References

* Todd, R (1994). "Gear Shaping", ''Manufacturing Processes Reference Guide''.Gear Shaping Machines

Retrieved on January 13, 2009. ;Notes {{DEFAULTSORT:Gear Shaping Gears